目录

ToggleIn today’s tough manufacturing world, having a dependable filling machine is very important. No matter if you work with food and drinks, medicine, beauty products, or chemicals, how well and accurately you fill your products affects their quality, how fast you make them, and how much money you make. This makes picking the right filling machine maker very important. This blog will help you understand important things to consider when choosing a filling machine manufacturer and why this decision is crucial for your business’s success.

What is a Filling Machine?

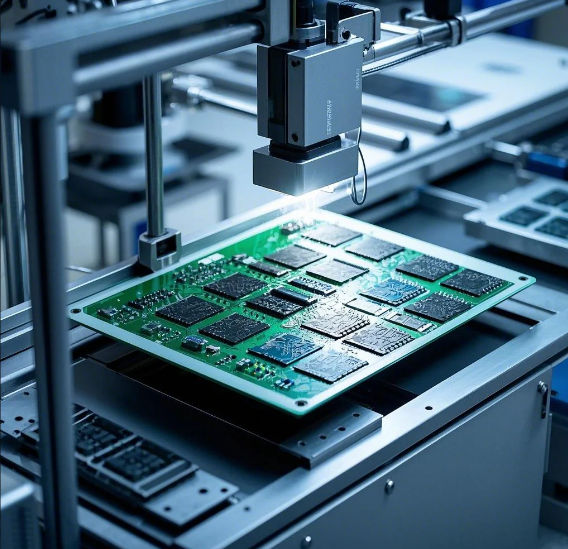

A filling machine is a device that puts the right amount of a product into bottles, jars, pouches, or cans. These machines are very important in factories that need to make a lot of products and keep their quality the same. There are different filling machines, like liquid, powder, and capsule fillers. Each type is made to work with certain products and packaging needs.

Why the Right-Filling Machine Manufacturer Matters

The choice of the company that makes your filling machines is very important for how well your production runs, the quality of your products, and the overall success of your operations. Here are some reasons why choosing the right filling machine manufacturer is important:

1. Product Quality and Consistency

The right manufacturer will provide machines that fill products accurately and evenly, which is important for keeping the product quality high. Wrong filling can cause wasted products, uneven results, and unhappy customers. A well-known company makes machines designed to meet your specific needs, whether you’re dealing with liquids, thick products, powders, or small grains. Customization makes sure the machine fits your specific production requirements.

2. Reliability and Durability

The best manufacturers use strong materials and parts to create their machines, making sure they last a long time and work well. This cuts down on how often things break and need repairs, which helps save money on operations. Top manufacturers use the newest technologies in their machines. This gives them features like automation, accurate controls, and the ability to connect with other equipment on the production line easily. This makes things work better and lessens mistakes made by people.

3. Compliance with Industry Standards

The right manufacturer makes sure their machines follow the rules and standards for different industries, like cleanliness in food and drink production or safety rules in medicine. Following these rules is important to prevent legal problems and keep customers safe. Well-known companies usually have certifications that show they care about quality and safety, like ISO certification, CE marking, or GMP compliance.

How to Choose the Right Filling Machine Manufacturer

When looking at filling machine manufacturer, think about these important points:

Good Experience & Scalability:

Choose manufacturers that have a strong history of working in your industry. They will have the right skills to meet your specific needs. Further, pick a manufacturer that provides machines that can grow with your production needs. This way, you won’t have to replace all your equipment as you expand.

Custom Solutions & Customer Reviews:

Make sure the manufacturer can adjust its machines to fit your custom or specific production needs, such as the kind of product, packaging, or certain industry rules. Read what customers say about the product to see if the manufacturer is known for making quality and dependable products.