目录

ToggleSurface Mount Technology (SMT) also known as pick and place machines has become a component of contemporary electronics production processes today. The integration of these machines enables SMT pick and place machine manufacturers to automate the placement of electronic parts, onto printed circuit boards (PCBs) ensuring both accuracy and efficiency are maintained at high levels. In this discussion, we will delve into the characteristics that distinguish an SMT pick and place machine manufacturer while examining the features that underline the significance of these machines, in PCB assembly tasks.

What exactly does an SMT pick and place machine manufacturers?

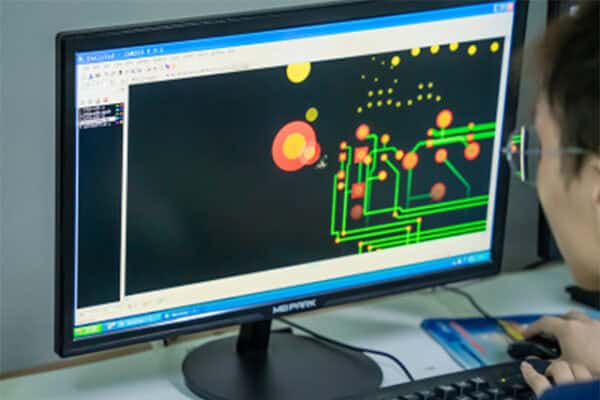

A pick and place machine, in surface mount technology (SMT), is a tool that positions surface-mounted components (SMDs) onto a printed circuit board (PCB) as part of the manufacturing process for devices. These machines are created to manage component sizes and shapes ranging from resistors and capacitors to larger integrated circuits. Automating this task with pick-and-place machines enhances efficiency and accuracy while ensuring results in electronics production.

Characteristics of SMT pick and place machine manufacturers

Manufacturers must carefully select an SMT pick and place machine that meets their requirements as it plays a role, in their operations.

High-Speed Placement: In high-speed assembly tasks, like SMT. In busy settings, place operations demand precision machinery that can handle thousands of components per hour efficiently and swiftly for productivity.

Accurate Component Placement: Precise Positioning of Components is crucial when it comes to small parts placement, in manufacturing processes. The use of systems and precise robotic arms plays a key role in ensuring accurate component placement which leads to lower error rates and overall improvement, in product quality.

Flexibility for Various Component Types: SMT. Place machines need to be versatile enough to manage kinds of components, in different sizes and shapes to ensure efficiency in setup and accommodate a varied production line.

User-Friendly Interface: Currently available machines often come equipped with a user interface that simplifies the task of overseeing and controlling operations while allowing for necessary adjustments to be made easily and efficiently This results in a decreased need, for extensive training of operators and helps to optimize the overall workflow.

Low Maintenance: Having machines, with low maintenance features can minimize the amount of time they’re, out of operation and lead to uninterrupted production while also lowering maintenance expenses.

Selecting the Appropriate Manufacturer; Why It Makes a Difference

Choosing the SMT pick and place machine manufacturers is crucial, for enhancing production quality and efficiency in your operations. Top-notch machines help streamline production timelines and enhance precision while also allowing flexibility in handling projects. A reputable manufacturer not only provides machines but also offers post-purchase assistance and training to support smooth operation in a dynamic production setting.

Conclusion

smt pick and place machine manufacturers serve as the core of SMT assembly lines, in industries to enhance electronics production efficiency; choosing a top-notch SMT pick-and-place machine from a known manufacturer can bring about lasting advantages such as higher production speeds and better product quality while minimizing downtime concerns. When deciding on a manufacturer to partner with for your machine needs it is vital to assess factors, like speed accuracy flexibility, and customer support to make sure the equipment meets your production requirements effectively.

0