目录

ToggleWhen designing electronic devices, one of the most critical components to consider is the MCPCB (Metal Core Printed Circuit Board). These specialized circuit boards are essential for managing heat dissipation in power-hungry electronics, making them crucial for industries ranging from automotive to consumer electronics. However, the performance and reliability of an MCPCB heavily depend on the quality of the MCPCB manufacturer you choose. This article discusses why selecting the right supplier is vital to the success of your product and how it can impact your electronic designs.

What is an MCPCB?

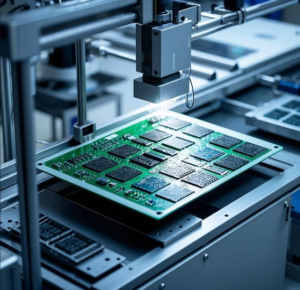

An MCPCB is a type of printed circuit board that features a metal base, typically made from materials like aluminum or copper, which allows for better thermal management compared to traditional FR4 PCBs. The metal core helps to dissipate heat more efficiently, ensuring that sensitive components such as LEDs or high-power processors remain cool during operation. As a result, MCPCBs are commonly used in applications like lighting systems, automotive electronics, and power supplies, where heat buildup can lead to reduced performance or failure.

Why is Choosing the Right MCPCB Manufacturer So Important?

Selecting a reputable MCPCB manufacturer is essential for ensuring the quality, durability, and performance of your electronics. A skilled manufacturer will not only have the technical expertise to create high-quality MCPCBs but will also offer customization options to meet the specific needs of your product. Below are some reasons why the right manufacturer matters:

1. Quality Control and Reliability

The manufacturing process for MCPCBs involves intricate steps, from selecting the right materials to ensuring proper heat treatment. An experienced MCPCB manufacturer will adhere to strict quality control processes to ensure that each board meets the highest standards. Consistency in manufacturing is key to avoiding defects that could affect the functionality and longevity of the final product.

2. Customization and Flexibility

Different applications require different designs, and a good MCPCB manufacturer will offer flexibility in customizing the boards to suit specific requirements. Whether you need a board with more layers, enhanced thermal conductivity, or custom dimensions, an experienced manufacturer will be able to tailor their offerings to meet your needs. Customization ensures that the MCPCB performs optimally in the intended environment.

3. Material Selection and Performance

The quality of materials used in the manufacturing of MCPCBs is directly linked to their thermal management capabilities. A reliable MCPCB manufacturer will have access to the best materials, ensuring that the MCPCB has superior heat dissipation properties, which is essential for power-intensive devices. Using the right metals, such as aluminum or copper, also contributes to the overall durability and efficiency of the board.

4. Cost-Efficiency and Timely Delivery

Choosing an experienced MCPCB manufacturer can also help you manage production costs effectively. A skilled manufacturer can streamline the production process, reducing waste and ensuring efficient use of materials. Additionally, a reliable supplier will deliver the boards on time, which is crucial for keeping your project on schedule and avoiding costly delays.

5. Support and After-Sales Service

A trusted MCPCB manufacturer will provide ongoing support throughout the lifecycle of the product. This includes technical assistance, quality assurance, and guidance on any design challenges. Having access to a knowledgeable support team can help resolve any issues quickly, ensuring the continuity of your operations without unnecessary interruptions.

Applications of MCPCBs

MCPCBs are used in a wide range of industries due to their excellent heat management capabilities. In automotive electronics, they are used in power control units and sensors. In the lighting industry, MCPCBs are commonly used in high-power LED lighting systems. Additionally, these boards are found in power supplies, telecommunications equipment, and industrial electronics, where reliable thermal performance is essential.

Conclusion

In conclusion, choosing the right MCPCB manufacturer is crucial for the success of any electronic device that requires efficient heat dissipation. From ensuring high-quality materials and reliable manufacturing processes to offering customization and support, the right supplier can make all the difference. By partnering with a reputable manufacturer, you can ensure that your MCPCBs are not only cost-effective but also perform optimally throughout the life of your product. Whether you’re designing for consumer electronics or industrial applications, selecting the right MCPCB manufacturer is a decision that should not be taken lightly.

0