目录

ToggleDesiccant air drying systems are widely used across various industries for applications that require drying air to a specific level of moisture. Depending on the scale and sensitivity of the application, different air drying systems are available to achieve optimal results. Among these, desiccant air dryers are a popular choice. In this article, we’ll discuss what makes them unique and how to choose the right desiccant air drying system for your needs.

What is a Desiccant Air Drying System?

A desiccant air drying system is a device designed to remove moisture from compressed air using a desiccant material. A desiccant is a porous, selectively permeable filter that allows only air to pass through while trapping moisture. Common desiccant materials used include silica gel, molecular sieves, and activated aluminum. These materials are chosen for their ability to absorb significant amounts of moisture relative to their size. Of these, molecular sieves and activated aluminum are often preferred due to their superior moisture-absorbing capabilities.

How Does a Desiccant Air Drying System Work?

Desiccant air drying systems typically use two towers or blocks in a process called pressure swing adsorption. In the first tower, compressed air flows in and is dried as it passes through the desiccant material. Meanwhile, the second tower works to restore and replenish the desiccant by removing the moisture it has absorbed. These two towers alternate, continually cycling between drying and regeneration phases, until the desired air dryness, or dew point, is achieved.

There are two main types of desiccant air drying systems: heatless and heated systems. Heatless systems rely on the recirculation of dried air to regenerate the desiccant, while heated systems use a combination of low temperature-high pressure and low pressure-high temperature conditions to remove moisture from the air more efficiently.

Why Choose a Desiccant Air Drying System?

When selecting a desiccant air drying system, there are several factors that can make a significant difference in its performance and suitability for your needs. A reliable desiccant air dryer should offer high drying capacity, low dew point, and customizable features for a tailored experience.

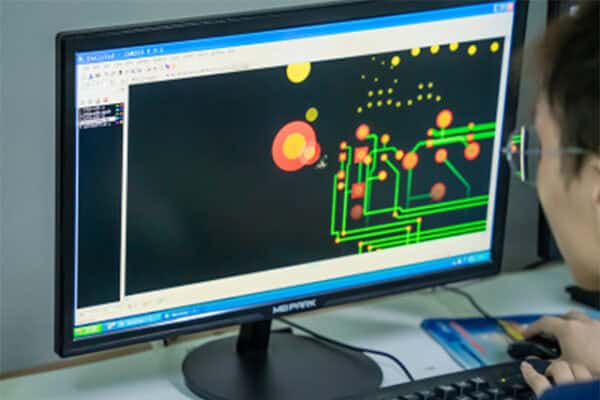

One of the key benefits of desiccant air drying systems is their ability to reach extremely low dew points, often as low as -70°C. This makes them ideal for industries where moisture in the air can negatively impact processes or products, such as in electronics manufacturing or pharmaceuticals.

Another advantage is the flexibility these systems provide. Many desiccant air drying systems come with additional features such as sound mufflers to reduce noise, stable outlet dew points for consistent performance, and high-quality valves for optimal efficiency. These features ensure a better experience for users and make the system more adaptable to various business needs.

Additionally, desiccant air drying systems can be customized to meet the specific requirements of businesses. Whether you need to adjust the drying modes or modify system components, there are options to suit various applications, from small-scale operations to large industrial applications.

Conclusion

Desiccant air drying systems offer effective moisture removal and can be tailored to meet the needs of different industries. Whether you require a heatless or heated system, these dryers provide a reliable solution for ensuring optimal air quality in various applications. When selecting a system, it’s important to consider the drying capacity, dew point, and customizable features to ensure it meets your business’s specific requirements. With the right desiccant air drying system, you can maintain consistent performance and improve the quality of your products and processes.

0