目录

ToggleElectronics have, for generations been through-hole circuit board. Considered very robust and a snap to manufacture, the THT has never fallen out of favor even to this day when the far sleeker SMT makes an entrance. The writer explores what through-hole circuit boards are, advantages that it possesses, common uses where it is applied and how it has fared against its other alternatives.

What is a Through Hole Circuit Board?

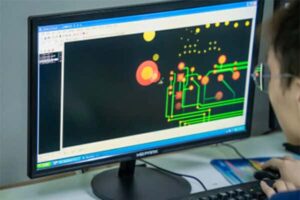

A through-hole circuit board is a PCB where its components have long leads or legs that pass through holes in the PCB, extending fully through it, where soldering to the opposite side is made possible. The design will therefore offer a strong, stable attachment of the components and the PCB.

Through-hole technology became very popular in the 1940s and remained widely used for decades to fabricate PCBs. Although surface-mount technology has largely replaced THT in most consumer electronics applications, there is still a value in using through-hole technology for applications requiring high reliability, such as industrial and military electronics.

Advantages of Through-Hole Circuit Boards

There are various advantages that make through-hole circuit board the best option for specific applications:

Durable: Through-hole connections are quite durable as compared to surface mount. Therefore, through hole technology is preferred in automotive, aerospace, and defense applications, where long duration reliability and ruggedness have been expected.

Ease of Prototyping: Through hole components are relatively easy to handle and solder by hand. Thus, they go very well for prototyping, repair, and DIY hobby projects, where components come to be easily added or replaced.

Compatibility with Older Parts: Many older electronic components are only available in the through-hole formats. With legacy parts, it’s crucial to have through-hole circuit boards for projects on aging equipment or repairs of ancient equipment.

Applications of Through-Hole Circuit Boards

Through-hole circuit board usually find their application where high reliability and ruggedness will be given priority over being small and light. Generally, the following will commonly use through-hole circuit boards:

Automotive Electronics: All cars and trucks demand quite reliable components that could offer resistance to the severe rigors of environmental exposures to vibrations.

Military and Aerospace Equipment: Here, in military-grade electronics, the equipment requires higher durability, so through-hole technology is more appropriate.

Industrial Equipment: Many industrial machines also use through-hole boards because they can tolerate some amount of stress and variation in temperature.

Audio Equipment: Audio devices are mostly preferred because of their analog quality sound, so, for some components, they use through-hole technology not to lose the quality of the signal. Through-Hole vs. Surface-Mount Technology (SMT)

Conclusion

Even though through-hole circuit board is no longer the most prevalent solution for high-density consumer electronics, they still have a very important position in applications where durability, reliability, and ease of assembly are required. Whether in automotive electronics, military equipment, or hobby projects, through-hole technology has proven its durability for decades. Even tried and tested PCB technology continues to meet such demanding applications where strength and resilience are of paramount importance.

0