目录

ToggleIntroduction to CNC Milling Advancements

The CNC milling process has been a cornerstone of manufacturing for decades, enabling the production of high-precision components for various industries. However, as technology continues to evolve, CNC milling is also experiencing significant advancements. These innovations are enhancing the capabilities of CNC milling machines, making them even more efficient and capable of producing complex parts with greater precision.

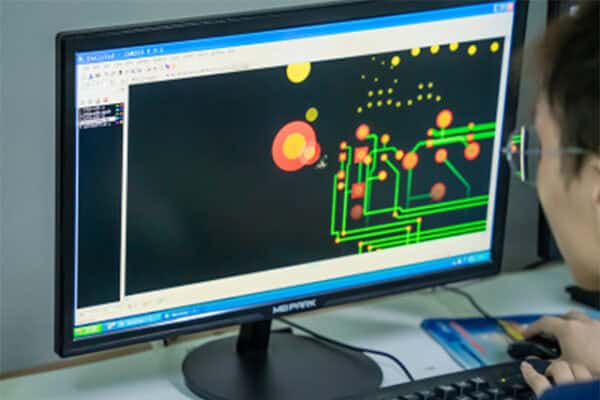

AI and Machine Learning Integration

One of the most exciting developments in the CNC milling process is the integration of Artificial Intelligence (AI) and machine learning algorithms. By incorporating these technologies into CNC systems, manufacturers can achieve higher levels of automation and predictive maintenance. AI-powered CNC milling machines can now optimize cutting paths and monitor tool wear, ensuring that the process is as efficient and cost-effective as possible. This can help reduce machine downtime and prevent errors during production, leading to improved overall efficiency. AI integration also allows machines to adapt in real time to variations in material properties or machine performance, making the process even more reliable.

Advanced Materials in CNC Milling

Another key innovation in the CNC milling process is the use of advanced materials. With the rise of new composite materials and alloys, CNC milling machines are being adapted to handle these more challenging materials. For instance, carbon fiber-reinforced polymers and titanium alloys are increasingly being used in industries like aerospace and medical devices. To accommodate these materials, CNC milling machines must be equipped with specialized tooling and cooling systems that can handle the increased stress and heat generated during cutting. This expansion of material capabilities has opened up new possibilities for manufacturers looking to produce lighter, stronger, and more durable parts.

The Rise of 5-Axis CNC Milling Machines

Additionally, the introduction of 5-axis CNC milling machines is significantly expanding the scope of the CNC milling process. These machines allow for greater flexibility, enabling manufacturers to produce more intricate and detailed parts without the need for multiple setups. The ability to work on multiple axes simultaneously makes the process faster and more accurate while also reducing the need for additional machinery. This results in shorter production times and less material waste, leading to lower production costs.

Hybrid CNC Milling and Additive Manufacturing

Additive manufacturing is another area where CNC milling is evolving. Hybrid machines that combine both milling and 3D printing technologies are emerging, allowing manufacturers to produce parts that are both lightweight and strong. These hybrid machines can 3D print certain features, such as complex internal structures, and then use traditional milling methods to finish the part to the desired specifications. This blending of technologies opens up new possibilities for creating parts with optimized designs that would have been difficult or impossible to manufacture with traditional methods alone.

Conclusion: The Future of CNC Milling

In conclusion, the future of the CNC milling process looks incredibly promising. With innovations in AI, advanced materials, and hybrid technologies, CNC milling is set to become even more efficient, versatile, and capable of producing even more complex and precise parts. As these advancements continue to unfold, the CNC milling process will remain at the forefront of manufacturing, enabling industries to push the boundaries of what is possible in product design and production.

0