目录

ToggleIntroduction

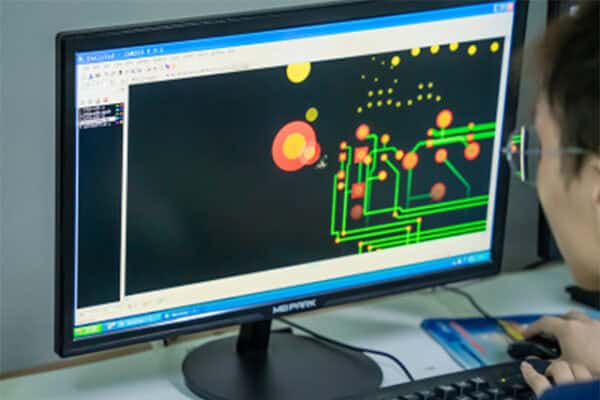

The evolution of electronics manufacturing has brought numerous advancements, one of the most impactful being Surface-Mount Technology (SMT). This method of assembling electronic components has revolutionized circuit board design by making production more efficient and allowing for smaller, more powerful devices. But what exactly is SMT meaning, and why does it matter in today’s world of electronics? This article explores the principles of SMT, its advantages, and its diverse applications across industries.

What Does SMT Meaning Refer To?

SMT meaning stands for Surface-Mount Technology, which is a technique for mounting electrical components directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole technology, SMT eliminates the need for drilling holes, enabling a more automated and precise assembly process.

With SMT meaning, manufacturers can produce circuit boards that are more compact, lightweight, and efficient, making them ideal for everything from consumer electronics to industrial automation.

Advantages of Surface-Mount Technology

- Higher Component Density – SMT meaning allows for more components to be placed on a single PCB, reducing the size while increasing functionality.

- Better Electrical Performance – Shorter electrical paths improve signal integrity, reduce interference, and enhance the overall efficiency of circuits.

- Faster and Cost-Effective Manufacturing – SMT-based production is highly automated, reducing labor costs and ensuring precise assembly with minimal errors.

- Improved Durability and Reliability – Components soldered through SMT technology are more resistant to vibrations and external stress, making them suitable for portable devices and harsh environments.

Industries That Rely on SMT Technology

The significance of SMT meaning extends beyond standard electronics manufacturing and influences several industries:

- Consumer Electronics: Smartphones, laptops, and smart home devices incorporate SMT for lightweight, efficient designs.

- Automotive Industry: Advanced safety systems, engine controls, and infotainment systems utilize SMT for enhanced performance.

- Medical Equipment: Precision electronic components in diagnostic tools and monitoring devices are developed using SMT technology.

- Telecommunications: High-speed networking devices and communication equipment benefit from SMT’s compact, high-performance design.

Conclusion

Understanding SMT meaning is essential for anyone looking to grasp modern electronics manufacturing. As industries push for smaller, faster, and more durable devices, SMT continues to be a cornerstone of technological innovation. Whether used in consumer electronics, automotive technology, or medical applications, SMT meaning represents efficiency, reliability, and progress in electronic design.

0