目录

ToggleThe process of turning raw materials into the everyday necessities we rely on is a fascinating blend of art, craftsmanship, and industrial engineering known as shoe production. Making shoes involves careful planning, skilled labor, and cutting-edge technology, whether it’s a pair of high-end leather boots or casual sneakers.

1. Design and Idea

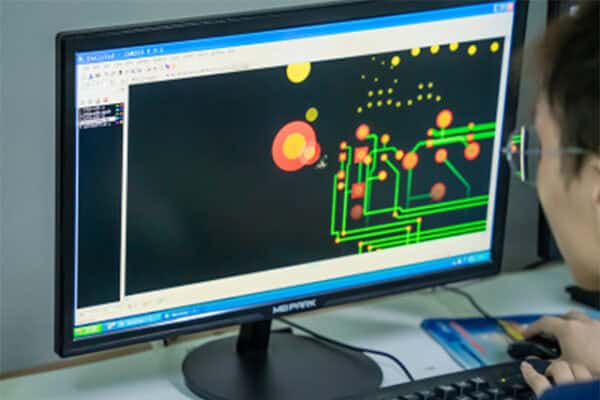

A concept is the beginning of every great shoe. When creating initial sketches, designers take into account consumer requirements, current fashion trends, and functionality. The planning stage includes choosing materials, deciding on the shoe’s construction, and settling on tasteful subtleties like tone and surface. Designers can now accurately visualize their ideas using cutting-edge technology like 3D modeling software and make any necessary adjustments before the actual prototype is produced.

2. Selecting the Material

When you want shoe production, choosing the right materials is very important. Some of the most common materials are rubber, foam, leather, and synthetic fabrics. Every material is picked in light of the shoe’s expected use — leather for sturdiness and extravagance, network for breathability in athletic shoes, and elastic for slip-safe soles. As consumers become more conscious of their impact on the environment, eco-friendly and sustainable materials are also gaining popularity.

3. Pattern Making and Cutting

The creation of a pattern is the next step after the design is complete in shoe production. The templates for the upper, lining, and sole of the shoe are called patterns. Talented craftsmen or specific machines slice the material as indicated by these examples. Accuracy in slicing is imperative to guarantee that each piece fits together impeccably during the gathering, limiting waste and ensuring the shoe’s solace and strength.

4. Stitching and Assembling

The upper part of the shoe is made by stitching the cut pieces together. Because the quality of the stitching affects the strength and appearance of the shoe, this process requires attention to detail. Depending on the kind of shoe, the upper and sole are then joined by stitching, adhesives, or a combination of the two. This process may involve several steps for more complex designs, such as high-end leather shoes, including shaping the upper on a last—a model foot—to ensure a proper fit.

5. Solid, long-term Attachment

The process of shaping the shoe’s production around the last to give it its final shape is called “lacing.” The upper material is held in place by being tightly pulled over the bottom. The sole is then connected, a basic step that decides the shoe’s solidness and solace. Some shoes fuse the sole and upper using direct injection molding, while others use adhesives or stitching as the method of attachment.

6. Final Touches

The shoes are finished by trimming off any excess material, polishing, and adding any final decorative elements after they have been assembled. Each pair goes through quality control checks to make sure they meet the brand’s standards. It determines and fixes any flaws, such as uneven stitching, loose threads, or loose soles that are not securely fastened.

0