目录

ToggleIntroduction to Footwear Manufacturing

Footwear manufacturing has undergone a remarkable transformation, evolving from simple handcrafting to highly automated processes. Today, it is a sophisticated industry that combines technology with creativity to produce shoes that are both functional and stylish. Let’s explore the key stages of footwear manufacturing and how the process has developed over time.

- Design and Prototyping

The journey of every shoe begins in the design phase. Designers work to create shoes that are not only visually appealing but also comfortable and durable. The design process has evolved with the use of computer-aided design (CAD) software, allowing for more precision and faster prototyping. After the initial concept, a prototype is created, often using 3D printing or other technologies to test the fit, shape, and function of the shoe before full-scale production begins.

- Material Selection

Material selection is a crucial step in footwear manufacturing. The materials used in shoe production must meet specific criteria, such as comfort, durability, and cost-effectiveness. Leather, rubber, synthetic fabrics, and EVA (Ethylene-Vinyl Acetate) are common materials, depending on the type of shoe being produced. In recent years, sustainability has become a key consideration, with more manufacturers opting for eco-friendly materials and production methods to reduce the environmental impact.

- Cutting and Preparing Components

Once the materials are chosen, the next step is cutting them into the necessary components. This includes the upper, insole, outsole, and lining of the shoe. In the past, this was a time-consuming manual process, but modern footwear manufacturing often relies on machines to cut the materials with high precision and efficiency. Automation has made this step faster and more accurate, ensuring that all parts of the shoe fit together perfectly.

- Assembly and Construction

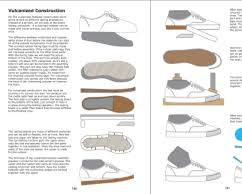

After the components are prepared, the assembly process begins. The upper part of the shoe is stitched together, and the insole is added. The outsole is then attached to the upper, usually through methods like gluing, stitching, or molding, depending on the shoe’s design. For more complex shoes, such as running or hiking shoes, advanced techniques like injection molding are used to create more durable, flexible outsoles. In many cases, this stage is a blend of manual craftsmanship and machine automation.

- Quality Control and Finishing

The final stage of footwear manufacturing is quality control. Each shoe undergoes a series of tests to ensure it meets the desired specifications for durability, fit, and comfort. This includes checking the stitching, examining the materials for defects, and ensuring the overall finish of the shoe. Many modern factories employ automated quality control systems that use cameras and sensors to detect any imperfections.

Evolution of Footwear Manufacturing

The history of footwear manufacturing is marked by innovation. Initially dominated by handcrafting, the industry shifted towards mechanization during the Industrial Revolution. The rise of automation and robotics in the 20th century further streamlined the process, increasing production speed and reducing costs. Today, cutting-edge technologies such as 3D printing, smart materials, and sustainable practices are reshaping the industry, allowing for customized shoes and reducing environmental footprints.

Conclusion

From the initial design to the final quality check, footwear manufacturing has become a highly sophisticated process. Advancements in technology and materials have allowed for faster production, improved quality, and more sustainable practices. As the industry continues to evolve, we can expect even more innovations that will shape the future of footwear production.

0