目录

ToggleIntroduction

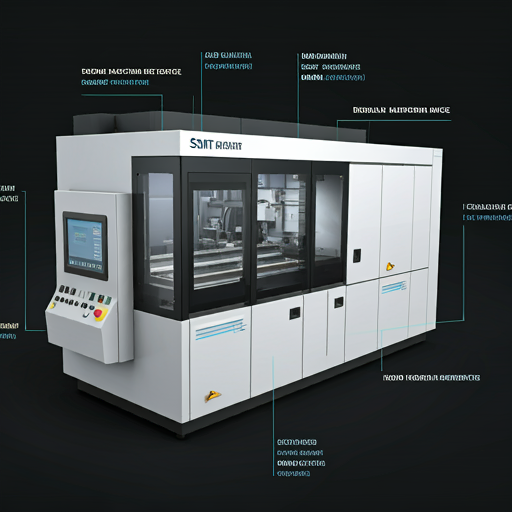

As the world becomes increasingly interconnected, the demand for cutting-edge electronic devices has grown exponentially. At the heart of this technological revolution lies SMT manufacturing (Surface Mount Technology), a transformative approach to assembling electronic components. By enabling compact, efficient, and reliable designs, SMT has become the backbone of the electronics industry.

What is SMT Manufacturing?

SMT manufacturing refers to the process of placing electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole assembly, which requires holes drilled into the PCB, SMT uses surface-mounted components. This not only saves space but also allows for high-density assembly, making it ideal for modern devices.

Key Steps in SMT Manufacturing

Solder Paste Printing

The process begins with applying solder paste to specific areas of the PCB using a stencil. This paste ensures strong electrical and mechanical connections between components and the board.

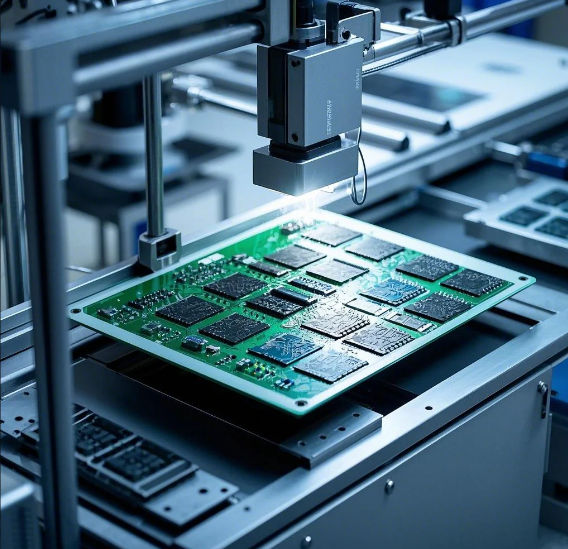

Component Placement

High-speed pick-and-place machines position components onto the PCB with unmatched precision. These automated systems can handle thousands of components per minute.

Reflow Soldering

The PCB assembly is sent through a reflow oven, where controlled heat melts the solder paste, securely bonding the components to the board.

Inspection and Testing

Advanced tools such as Automated Optical Inspection (AOI) systems and X-ray machines check for alignment, solder quality, and any potential defects.

Final Assembly

Once inspected, the PCB is integrated into its final product, such as a smartphone, automotive system, or medical device.

Advantages of SMT Manufacturing

Compact Designs

SMT allows for high-density component placement, enabling smaller and lighter devices that meet modern consumer demands.

High-Speed Production

Automation in SMT manufacturing ensures rapid assembly without sacrificing quality, making it ideal for mass production.

Cost Efficiency

By reducing manual labor and material waste, SMT significantly lowers production costs.

Enhanced Reliability

Surface-mounted components are more resistant to vibration and mechanical stress, ensuring durability across applications.

Design Flexibility

SMT supports a wide range of components and layouts, enabling innovative and complex designs.

Applications of SMT Manufacturing

Consumer Electronics

Devices like smartphones, laptops, and smartwatches rely on SMT for their compact designs and advanced functionalities.

Automotive Systems

SMT powers critical components in modern vehicles, including engine control units (ECUs), advanced driver-assistance systems (ADAS), and infotainment modules.

Medical Devices

Precision instruments such as portable health monitors, diagnostic equipment, and imaging systems are made possible through SMT manufacturing.

Telecommunications

High-frequency circuit boards for 5G networks, IoT devices, and routers benefit from SMT’s scalability and efficiency.

Industrial Automation

Factory automation systems and IoT-enabled machinery use SMT-assembled PCBs for optimized performance and connectivity.

Emerging Trends in SMT Manufacturing

Miniaturization

As electronic devices shrink, SMT manufacturing is evolving to handle ultra-small components and densely packed PCBs.

Flexible and Wearable Electronics

SMT is adapting to flexible PCBs, enabling innovations in wearable technology and foldable devices.

Sustainable Practices

Eco-friendly initiatives such as lead-free soldering and energy-efficient production are reshaping SMT manufacturing.

Industry 4.0 Integration

Smart factories equipped with AI, robotics, and IoT technologies are revolutionizing SMT production, improving quality and efficiency.

Advanced Materials

The development of new solder alloys and high-performance substrates is expanding the capabilities of SMT for demanding applications.

Future Outlook for SMT Manufacturing

The evolution of SMT manufacturing aligns closely with the advancements in artificial intelligence (AI), augmented reality (AR), and sustainable technology. As industries push the boundaries of innovation, SMT will remain at the forefront, providing the foundation for next-generation devices. Its ability to support complex, high-performance designs while ensuring efficiency makes it an indispensable part of modern manufacturing.

Conclusion

SMT manufacturing has transformed the electronics industry by enabling compact, reliable, and high-speed production. Its versatility and precision have paved the way for revolutionary advancements across multiple sectors, from consumer electronics to industrial automation. As SMT continues to evolve, it will shape the future of technology, driving progress and innovation in an ever-changing digital world.

0