目录

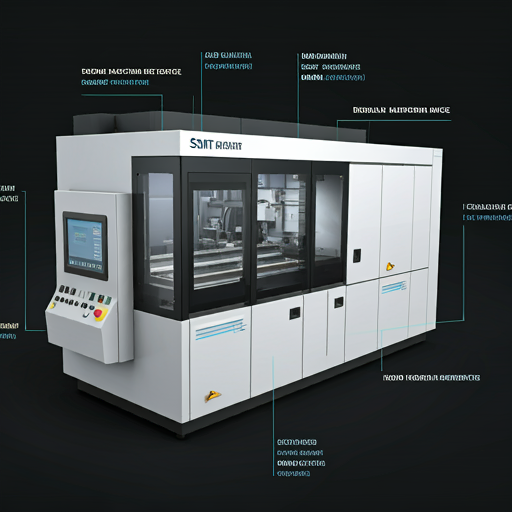

ToggleIn today’s competitive manufacturing landscape, efficiency and precision are vital. One of the key machines that help industries maintain these standards is the automatic capping machine.

These machines provide a fast, reliable solution for sealing containers, ensuring consistent quality in a range of industries such as cosmetics, food and beverage, pharmaceuticals, and more.

What is an Automatic Capping Machine?

An automatic capping machine is a piece of equipment designed to automatically cap bottles or containers with minimal human intervention.

Whether it’s screwing on caps, corking bottles, or snapping lids into place – these machines are widely used for their efficiency and accuracy.

Types of Automatic Capping Machines

There are various models of automatic capping machines, each tailored to specific applications. Below are some examples of popular machines:

Servo Automatic Lotion Pump Bottle Capping Machine: Ideal for cosmetic and personal care products, this machine is used to cap lotion pump bottles with high precision.

Automatic 8 Heads Liqueur Wine Corking Equipment: Commonly used in the wine and spirits industry, this machine efficiently corks bottles in large volumes.

Automatic Olive Oil Soda Bottle ROPP Capping Machine: This machine is perfect for industries requiring roll-on pilfer-proof (ROPP) caps, such as olive oil or soda bottling.

Applications of Automatic Capping Machines

Automatic capping machines serve a wide range of applications across multiple industries. Their ability to handle different cap and bottle sizes makes them a flexible choice for businesses.

Here are a few key sectors where they are commonly used:

Cosmetics and Personal Care: Machines like the Servo Automatic Lotion Pump Bottle Capping Machine are essential in ensuring the precise sealing of lotion bottles, creams, and serums, contributing to both product quality and appearance.

Food and Beverage: From bottling wine with the Automatic 8 Heads Liqueur Wine Corking Equipment to sealing olive oil or soda with an Automatic Olive Oil Soda Bottle ROPP Capping Machine, the food and beverage industry relies heavily on these machines for efficiency and consistency in production.

Pharmaceuticals: Precise capping is critical in the pharmaceutical industry to prevent contamination and ensure proper dosage. Automatic capping machines guarantee a secure and sterile seal on medication containers.

Household Products: For products like cleaning supplies, chemicals, and detergents, automatic capping machines offer a reliable solution for quickly and safely sealing a variety of containers.

Benefits of Using an Automatic Capping Machine

1. Increased Efficiency

One of the primary advantages of an automatic capping machine is the increase in production speed. For example, multi-head machines like the Automatic 8 Heads Liqueur Wine Corking Equipment can cork several bottles simultaneously, significantly boosting production output.

2. Consistency in Sealing

Manual capping can lead to inconsistent sealing, with some caps being too loose or too tight. In contrast, an automatic capping machine ensures uniform application of caps across all containers, whether using screw caps, corks, or ROPP caps.

3. Versatility

Automatic capping machines are incredibly versatile. Whether you’re capping lotion bottles, wine bottles, or olive oil containers, these machines can handle a variety of applications. For instance, the Automatic Olive Oil Soda Bottle ROPP Capping Machine can be used for both oil and carbonated beverages.

4. Reduced Labor Costs

Since the machine performs the capping process autonomously, the need for manual labor is greatly reduced. Businesses can optimize their workforce for other tasks, lowering labor costs and improving overall productivity.

So it is permissible to say that an automatic capping machine is an essential investment for businesses looking to improve efficiency, maintain consistency, and ensure product quality.

0