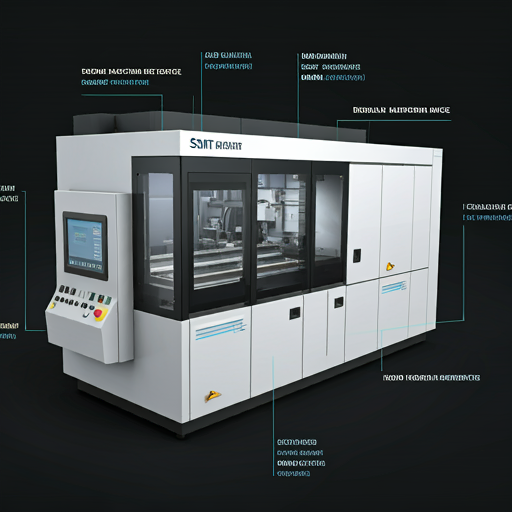

Automation technology has revolutionized the sheet metal welding process, offering significant advantages in efficiency, precision, and consistency. By integrating advanced robotic systems and software, manufacturers can achieve superior results, ensuring that modern production demands are met with ease.

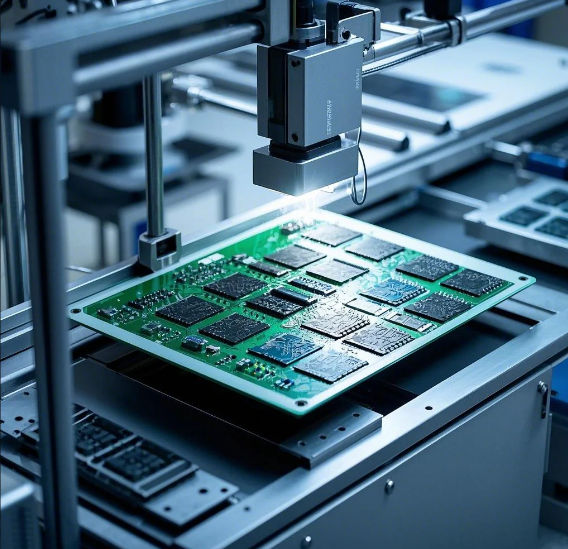

One of the most notable benefits of automation technology in the sheet metal welding process is the enhancement of precision. Robotic welders are programmed to perform intricate welds with unmatched accuracy, minimizing errors and deviations. This level of precision is crucial in industries requiring high-quality finishes, such as automotive and aerospace sectors.

Another key advantage of automation technology in the sheet metal welding process is its ability to improve productivity. Automated systems can operate continuously, drastically reducing production times compared to manual welding. This is especially beneficial in large-scale manufacturing, where speed and efficiency are paramount.

Consistency is another area where automation technology excels. In the sheet metal welding process, achieving uniform welds across multiple pieces can be challenging when done manually. Automation ensures repeatability, producing identical welds regardless of batch size. This consistency leads to fewer defects and a reduction in rework, ultimately lowering production costs.

Moreover, automation technology contributes to workplace safety during the sheet metal welding process. Welding involves high temperatures, sparks, and potentially hazardous fumes. By employing automated systems, human workers are removed from direct exposure to these dangers, creating a safer work environment.

In conclusion, the effectiveness of automation technology in the sheet metal welding process is evident in its ability to enhance precision, improve productivity, ensure consistency, and promote safety. As manufacturing continues to evolve, the integration of automation will remain a vital component for achieving superior outcomes in the sheet metal welding industry.

0