目录

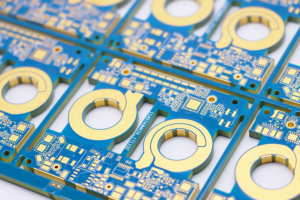

TogglePrinted Circuit Boards are the most important components for electronic gadgets. They provide the best platform that allows electrical elements to interact with each other. However, copper plating is a vital step in manufacturing the boards. This process ensures the board efficiently conducts electricity. The multi-step procedure involves cleaning and preparing the board surface to create a bond with the copper layer.

Why choose a copper-plated PCB board?

There are several reasons for investing in copper-plated PCBs.

- Improved conductivity for better appearance

With superb electrical conductivity, copper is perfect for manufacturing a Printed Circuit Board. Copper plating on the board allows manufacturers to improve the PCB’s potential to conduct electricity. It is a vital factor for superb performance and high-speed applications. Higher conductivity minimizes the signal loss and facilitates faster transmission of the signal across your board. For instance, computing and telecommunication devices need a high-quality copper-plated PCB board. - Efficient thermal management

When you use your electronic gadgets continuously, they produce heat. Without proper thermal management, your electronics will degrade, and the electronic components may be damaged. Moreover, copper efficiently conducts heat away from the delicate parts of the board, resulting in a safe operating temperature without overheating risks. - A long-lasting choice

Copper plating makes your Printed Circuit Boards more durable and protects them from corrosion. A copper layer allows the board to resist physical stress and extreme conditions. So, copper-plated PCBs have a longer operating life and resist environmental elements (such as temperature fluctuations and humidity). - Make PCB reliable for electronics

Power management is the most significant factor in designing electronic items. Copper plating improves the PCB’s ability to deal with higher currents. That is why copper-plated PCBs are best for manufacturing electronics that need consistent power flow. They can endure extreme current loads without affecting performance. - Compact design

Modern electronics are more compact to ensure users’ convenience. Manufacturers look for innovative ways to reduce the component’s size. Copper-plated printed circuit boards efficiently conduct electricity, allowing smaller models with fewer layers. Thus, the end products will be more compact and lightweight.

A cost-efficient solution

Though copper-plated PCB board manufacturing involves a costly process, its improved performance and durability will save you costs in the long run. The PCB with copper plating does not need frequent replacements. So, invest in the copper-plated Printed Circuit Board that performs at the optimal level.

Applications of copper-plated PCBs

A copper-plated PCB board has a range of applications:

- Automotive- Copper PCBs are highly essential for designing EVs and motor controllers in the automotive sector.

- Renewable energy- The potential to endure heat and high power levels makes copper-plated PCBs a perfect choice for wind turbine controllers and solar inverters.

- Medical equipment- Medical devices have diverse performance needs and rely on thick copper PCBs. For instance, diagnostic instruments and medical imaging devices need these Printed Circuit Boards for operation.

You can now search for the best vendor to buy a copper-plated PCB board for your electronics.

0