目录

ToggleLED technology is now very important in many areas, including electronics, cars, and factories. A main part that makes LED systems work well is the LED circuit board. In this blog, we will look at what LED circuit boards are, their benefits, where they are commonly used, and why they are important for today’s lighting solutions.

What is an LED Circuit Board?

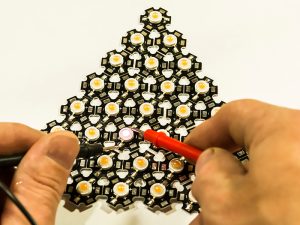

An LED circuit board is the main part that holds and connects LED parts. It usually includes a board with lights (LEDs) attached to it, along with parts that help it work, like resistors, capacitors, and drivers. The board makes sure power is spread out well to the LEDs and controls heat, which is important for keeping them working well for a long time.

LED circuit boards come in different kinds, but the most common one is the metal-core PCB (MCPCB). These boards are made to control the heat from powerful LED lights. Unlike regular PCBs made from fiberglass, metal-core PCBs are made from materials like aluminum or copper, which conduct heat better.

Advantages of LED Circuit Board

- Effective Heat Release:

LEDs give off heat while they work, and too much heat can lower how well they work and shorten their lifespan. LED circuit boards, especially the metal ones, spread out heat better, helping LEDs work well. - Energy Efficiency:

LED lights use very little electricity. LED circuit boards are made to spread power effectively, helping the LEDs shine bright while using very little energy. - Small and Light:

LED circuit boards are small and light, which makes them great for places where there isn’t much space. This is especially helpful in areas like electronics, where products should be small but still very strong. - Customizable Design:

Makers can change LED circuit boards to fit the specific needs of a project. Custom LED boards can be made in different shapes, sizes, and designs to fit specific lighting needs for different uses. - Cost Effective:

Good heat control and smart power use help LEDs last much longer than regular lights, which lowers maintenance and replacement costs.

Applications of LED Circuit Board

- Automotive Industry: LED circuit boards are commonly used in car lights, such as headlights, taillights, and inside lights. LEDs use less energy and last a long time, making them perfect for cars, where being tough and saving power are important.

- Consumer Electronics: LED circuit boards are used in items like smartphones, TVs, and computers for lighting and showing images. Their small size and low energy use make them ideal for these uses.

- Industrial Lighting: Factories and workplaces often need bright lights that can handle tough conditions. LED circuit boards, especially those made of aluminum, are commonly used for lights in factories, large outdoor lights, and lighting in industrial areas.

Conclusion

LED circuit boards are important parts of modern lighting systems. They save energy, last a long time, and can be made to fit different needs. If you’re creating lights for home gadgets, factories, or cars, LED circuit boards are a great choice because they are dependable and last a long time.

0