目录

ToggleWith so many PCB service providers around the world, it can be very difficult for OEMs to find a long-term PCB manufacturer or assembler (hereafter we’ll refer to it as a PCB maker). This article provides some guidance on how to pick the most suitable PCB vendor from a long waiting list.

The printed circuit board is the heart of the electronic product, and its quality will directly affect the application and performance of the final product. Therefore, the first principle of evaluating PCB makers to check the condition of their products, which can be carried out in three aspects: quality, industry, and cost.

1 Quality

Everyone craves high quality, and this stems from the following aspects:

- Whether SPC is applied in the printed circuit board manufacturing process, such as component CPK control or manufacturing management diagrams;

- Whether there is continuous improvement in quality management, such as QCC or TQM;

- Whether ECO (Engineering Change Order) management applies;

- whether the principle of relinquishing control of the component is published in its terms and conditions;

- Compliance with rigorous quality control assessments, including material inspection records and management, SMT yield, AQL levels, document management, BOM preservation, ESD implementation, and equipment calibration;

2 Industry

Printed circuit boards are used in many different industries, and specific industries have strict and special requirements for their manufacturing standards. It is almost impossible for PCB factories to cover all industries. In general, they tend to be better at serving certain industries and less so at others. eg, a PCB maker that is proficient in mobile phone circuit board processing must have rich experience to limit the space in the final product, while a PCB maker that primarily serves the aerospace industry will certainly perform better in terms of high density.

In this case, it’s important that you have a good understanding of the industry you’re investigating that PCB Houses is good at dealing with, so you’ll be working with a professional partner rather than a one-size-fits-all partner.

3 Cost

While there are many tips for reducing the cost of PCB assembly, price is sometimes the main factor that drives us to make the final decision. As a necessary consideration when choosing a PCB manufacturer, cost should be analyzed from two aspects:

- Overall Offer – Don’t get caught up in the enticing numbers themselves. Reliable PCB manufacturers will be responsible for every word they claim. You should make sure that the price given to you by their salesperson is a full price without any hidden or post-order additional costs;

- Ongoing cost reduction – This refers to offering some discounts on your order. While PCB manufacturers will never offer you consistently low prices, you can expect to receive ongoing discounts when you order again, such as free tooling fees, etc. This strategy is a solid foundation for long-term cooperation;

As mentioned above, product quality is the soul of PCB manufacturers, and the ability of PCB manufacturers depends on product quality. PCB manufacturing and assembly capabilities can be reflected in the following aspects:

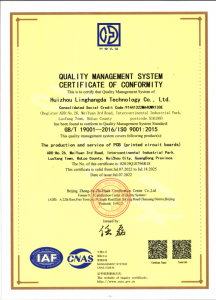

1). Certificates

The certificate represents the true manufacturing capability of the enterprise. Working with PCB fabs that are certified to standards such as ISO9001:2008, UL, RoHS, etc., you can rest assured that they will strictly adhere to the provisions of these certifications for high-quality products.

2). Technology

Aspects related to the technology of the PCB fab surveyed can be summarized as follows:

- whether the technology used meets your requirements and whether the processing capacity meets your requirements;

- State-of-the-art equipment for processing or automation;

- whether there is a creative expression in technology;

- Ability to lead the market with new processing methods;

- Processing capacity assessment;

- BGA integrated circuit repair capabilities

- 0201 or 01005 welding and repair capabilities;

- Ability to enforce RoHS;

- Integrity of standard operating procedures;

- How to correct incorrect material selection and negative polarity;

- review circuits and provide DFM services;

- Humidity sensitivity (MSL) element control capability;

- Solder paste temperature return, sealing, and shelf-life management functions;

- Removal of panel processing capabilities